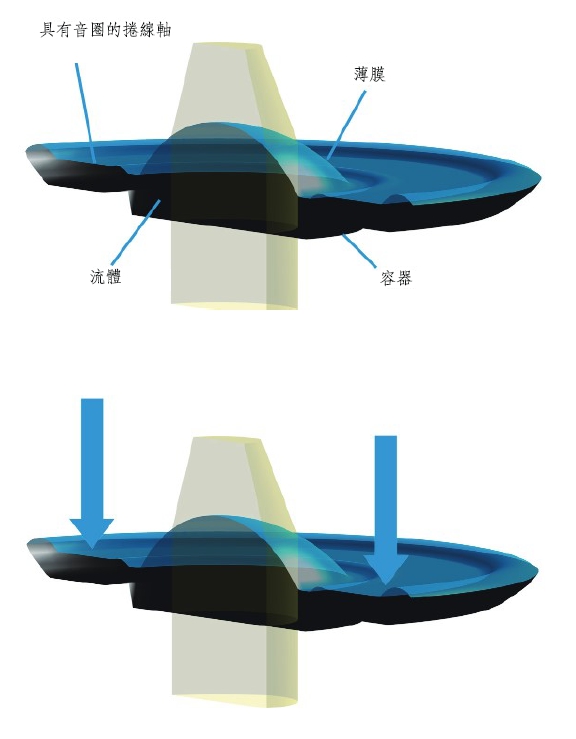

Working principle of Optotune’s manual lens ML-20-35, which achieves a lens shape ranging from concave to flat to convex. The ring that forms the lens is pushed towards the container, thus filling the lens with liquid |

[技術分享] 液態可變焦透鏡原理 Focus tunable lenses

Introduction

Traditional optics are based on solid glass or plastic lenses, which are moved back and forth to focus or zoom. A very old but successful system, however, is completely different: the eye! It consists of an elastic lens material, which is bent in order to focus. Optotune has developed and patented a series of lenses that basically copy the principle of the eye.

Instead of moving lenses back and forth, the human eye focuses by reshaping its lens

Working principle

Optotune’s focus tunable lenses are shape-changing lenses based on a combination of optical fluids and a polymer membrane. The core element consists of a container, which is filled with an optical liquid and sealed off with a thin, elastic polymer membrane. A circular ring that pushes onto the center of the membrane shapes the tunable lens. The deflection of the membrane and with that the radius of the lens can be changed by pushing the ring towards the membrane or by exerting a pressure to the outer part of the membrane or by pumping liquid into or out of the container.

Working principle of Optotune’s electrical lens EL-10-30. In this case, the lens-shaper ring remains in place relative to the container. The only movement is a ring that pushes down on the membrane in the outer part of the lens with increasing current, thus pumping the liquid into the center of the lens.

Possible variations of the shape-changing polymer lens

Advantages

A change in lens radius of several micrometers can have the same optical effect as moving the entire lens several centimeters. Optical systems can be designed more compact, oftentimes with less lenses and usually with less or no translational movement. Accordingly, there is no more need for expensive mechanical actuators. Less movement also leads to a more robust design, which can be completely closed so that no dust can enter. Furthermore, the materials employed are lighter than glass, saving overall weight. Less movement and weight also means less power consumption and that the response time of systems with tunable lenses can be very low, in the order of milliseconds. Another advantage becomes obvious during production. The fact that less optical parts are moved combined with the tunability of the radius during operation results in reduced tolerance sensitivity and thus higher yield rates.

To summarize, these are the five main advantages of focus tunable lenses over traditional optics:

- Compact design

- Less mechanics

- Fast response

- Low power

- Less tolerance sensitivity

技術

工作原理

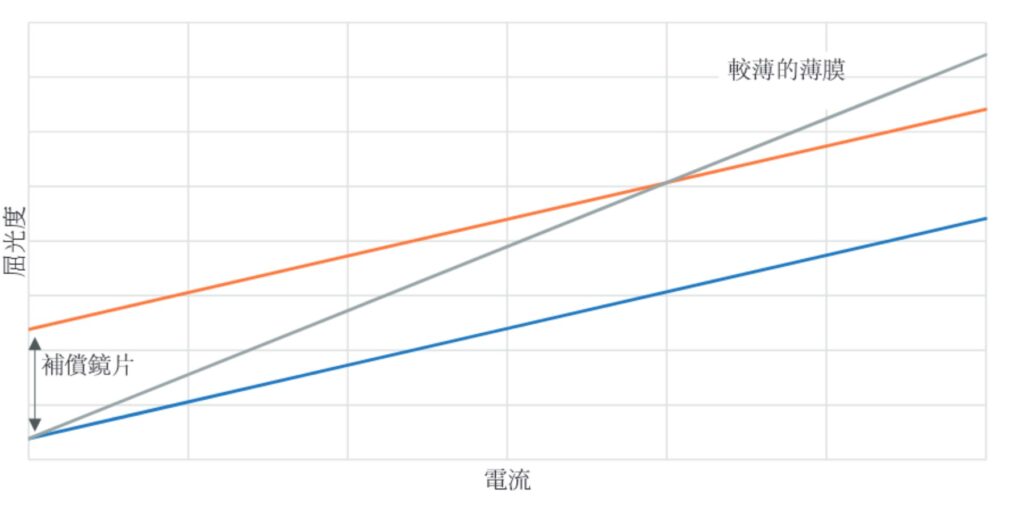

Optotune的核心技術是基於可變形鏡頭的工作原理。 鏡頭是由一個容器組成,容器內裝有光學流體,並用 彈性聚合物薄膜進行密封。電磁致動器對容器施壓後 進而導致鏡頭彎曲,從而通過致動器線圈內的電流來 控制鏡頭的焦距。實際上,電流和屈光度(與焦距成反 比)成線性關係。

大多數可調焦液態鏡頭均設計呈正方向彎曲,即致動器朝薄膜方向推進。通常需要增加一個平凹補償鏡片以實現負屈光度。但新一代鏡頭的驅動器與薄膜相連接,可通過負電流將薄膜推離容器,從而形成凹透 鏡頭。因此,無需額外添加補償鏡片便可實現負屈光度。

薄膜厚度是影響鏡頭調焦範圍的重要參數。薄膜厚 度越小,屈光度調節範圍越大。此外,鏡頭的屈光度還可以通過使用折射率不同的光學流體來進行調整。 Optotune採用折射率為約1.3的光學流體,具有低色散特性(阿貝數約為100),這使得鏡頭極其適合用於 多色應用領域。

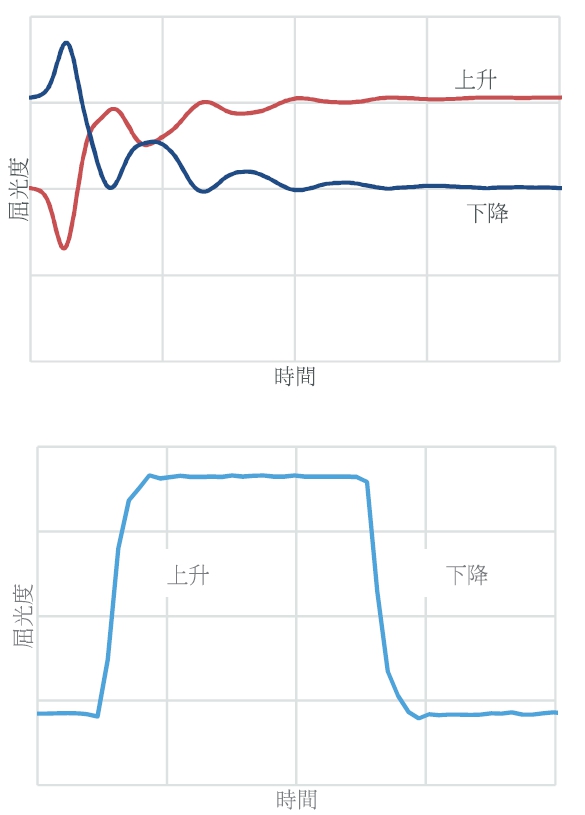

反應時間

與質量彈簧系統類似,液態鏡頭需要極短且有限的反應時間作動,其原因在於致動器移動必需克服流體的物理慣性。當採用階躍電流時,鏡頭的上升時間大約為幾毫秒。由於共振激發的作用,鏡頭僅需10-20毫秒即可完全就位,具體所需的時間還與鏡頭尺寸有關關。右圖顯示了鏡頭對階躍電流的光學影響,其結果由四象限光電二極管測得。測量均在室進行。

採用經優化的階躍電流或閉環系統可大幅抑制共振。右圖為EL-10-4 2-0F鏡頭的楷形響應,該款鏡頭帶有用於閉環屈光度控制的整合光回饋系統。結果顯示未出現振盪現象。

波前品質

大致上Optotune的可調焦液態鏡頭呈現球面透鏡的形狀。波前誤差一般約為0.1 (測量條件:8mm通光孔 徑,波長為525 nm),可進行高品質成像和顯微檢查。通常薄膜厚度越薄,調節範圍越大,但同時波前誤差也會變大。如右圖中藍、紅實線所示。

由於薄膜具備彈性,因此鏡頭形狀會受到重力影響。 當鏡頭垂直使用時(光軸為水平方向),會因重力而產 生Y軸慧(Y-Coma)。右圖紅線虛線和實線充分證明了這一點。我們還可以從這些虛線和實線中看到薄膜越厚,質地便越硬,因而受到重力的影響越小。因此,為了使鏡頭發揮最佳的性能,建議將光軸置於垂直方向。

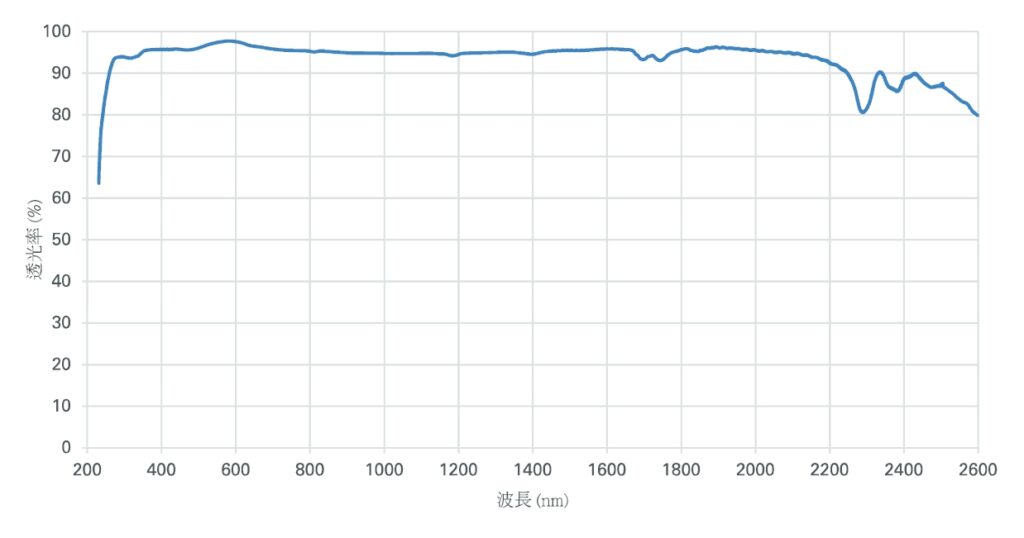

透光率

光學流體和薄膜材料均具備極高的透光性,透光波段為400-2500 nm。以下透射光譜儀表示透鏡材料的透光率,如:假設採用了理想的蓋玻片。由於薄膜具有彈性,因此無法使用標準程序鍍膜,所以薄膜反射率為4%,如有需求,我們可以再蓋玻片上針對特需波長進行鍍膜優化處理。 Optotune對於蓋玻片提供兩種在可見光和近紅外光區域 的標準寬波段鍍膜。如有需求,我們可對蓋玻片進行特殊鍍膜處理。

驅動器和控制模式

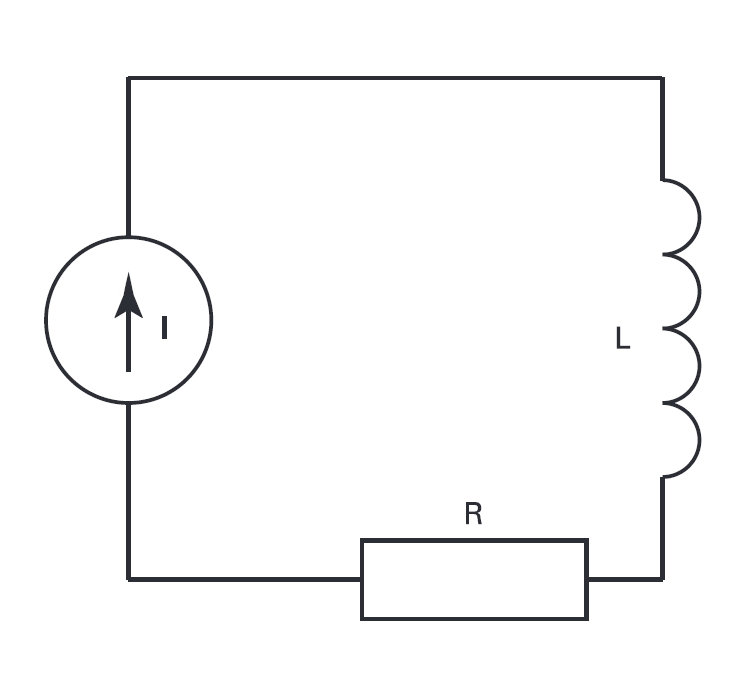

Optotune電動可調焦液態鏡頭採用LR電路,作為描述 其一般行為的等效電路,如右圖所示。

通常可使用標準電流源來驅動電動可調焦液態鏡頭,但Optotune為客戶提供專用電子元件驅動鏡 頭。Optotune Lens driver 4 和41 可簡單便捷地驅動 Optotune 生產的大多數電動可調焦液態鏡頭。緊湊設計的鏡頭驅動器為可編程的電源流,其可透過類比序

列埠(COM port)或UART通訊介面進行控制。該鏡頭驅動器既可獨立運行,也可整合到OEM用戶的設計之中。

用戶可選擇不同的控制模式,如”電流模式”和“屈光度模式”。在屈光度模式下,驅動器會將鏡頭當下的 工作溫度和內部校準數據作為參考依據,因此溫度效應引起的焦點漂移狀況得到了大幅的改善,亦能保持 屈光度其恆定狀態。

特定鏡頭如EL-10–42–OF還支援基於光學回饋的閉環運 行功能。L-E-OF電子元件可控制具備光回饋功能的鏡頭,從而實現最高的精準度和對焦穩定性。